Circuit breakers are essential electrical mechanisms in any power distribution or control system. Their main function is to establish or interrupt the passage of electrical current in a controlled manner, thus ensuring operational safety and protection of equipment and conductors.

Depending on their design and application, circuit breakers can be classified into multiple categories. In the residential field, they allow to control light points or electrical devices in a simple way. In industrial or commercial installations, they play a more complex role in the protection of motors, power lines and control circuits.

The choice of the right type of circuit breaker depends on factors such as rated voltage, operating current, breaking capacity and installation environment.

In the following, you will learn about the main types of electrical circuit breakers, their principle of operation, the most common applications and their schematic representation. This knowledge is essential for the design and maintenance of safe, efficient and compliant electrical systems.

Manual switches

Manual switches are those that require the direct action of a person to open or close an electrical circuit, allowing to turn on or off a device according to the user’s need. They are the most basic and widely used, present in both domestic and industrial environments.

These switches have no internal automatism. Their status depends exclusively on the manual position of their contacts.

Main applications of manual switches

- Residential use: Light switches (single, switched or crossover) or buzzer pushbuttons.

- Industrial use: Control pushbutton panels, selectors and manual controls to start or stop specific machine or process functions. In these cases, human intervention is essential to ensure safety and direct control of operations.

Productos recomendados

Ver Productos

Ver Productos

Ver Productos

Ver Productos

Common types of manual switches

Toggle switches: They operate by moving a lever to open or close the circuit. They are common in simple control systems.

Rocker switches: Switch between two positions (ON and OFF) by a rocking motion. They are used in industrial or commercial environments.

Momentary or latching pushbuttons: Pushbuttons are only active as long as the button is held down. The interlocking ones maintain the status after the pushbutton is released.

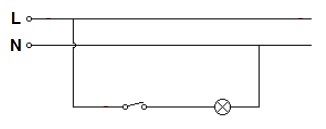

Typical diagram

The simplest schematic is that of a simple switch that turns a light bulb on and off.

Circuit Breakers

Circuit breakers are reusable protective devices designed to interrupt the flow of current automatically when abnormal conditions are detected in the circuit, such as overloads, short circuits or leaks.

They consist of a tripping mechanism that opens the contacts without human intervention. Depending on the type, this mechanism may be based on magnetic, thermal or other sensors that monitor circuit conditions.

These circuit breakers are essential to protect both people and domestic and industrial electrical installations, preventing damage to equipment and minimizing fire hazards. Unlike fuses, circuit breakers have the advantage of being able to be reset after troubleshooting.

Main applications of circuit breakers

- Electrical safety in domestic installations: In residential distribution panels, they protect electrical circuits against overcurrents, preventing damage to equipment and reducing the risk of fire.

- Industrial protection: In industrial environments, circuit breakers are key to protecting high amperage equipment and ensuring the safety of installations, disconnecting power instantly when a problem is detected.

Common types of circuit breakers

Within this category are circuit breakers (to protect against overloads and short circuits), earth leakage circuit breakers (for protection against earth leakage and electrocution) and high amperage devices for industrial applications.

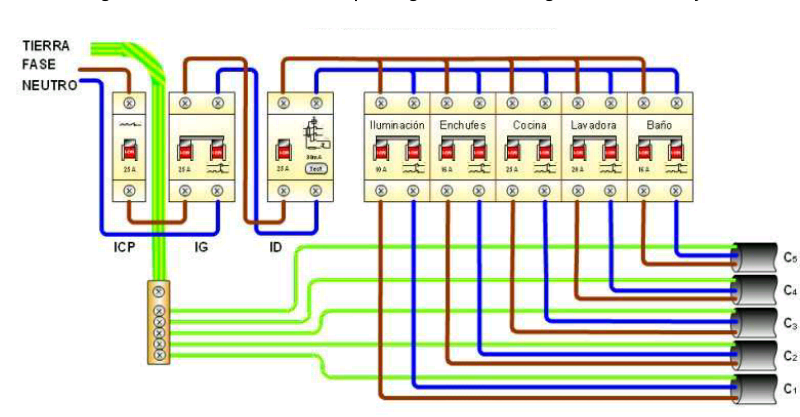

Diagram of circuit breakers in electrical panels

Diagram of a domestic electrical panel showing the connection of several circuit breakers.

Programmable Circuit Breakers

Programmable switches, also known as timers, are devices equipped with time or electronic control mechanisms that allow circuits to be activated or deactivated according to a predefined program.

These switches are ideal for automating the switching on and off of equipment, without the need for manual intervention, at specific times or intervals.

Main applications of programmable switches

- Lighting control: They are used to control outdoor and indoor lighting at specific times, which is useful for both safety and energy efficiency.

- Scheduled air conditioning and heating: They can be used to manage heating or air conditioning systems, ensuring that they are turned on or off at precise times, such as in the morning or before arriving home.

- Automatic irrigation: They are ideal for irrigation systems in gardens, activating irrigation during the hours of lower evaporation.

- Commercial signs: They are used to turn on or off illuminated signs at programmed times.

- Industries: In industrial environments, they are applied in processes that require repetitive and timed operations, such as the control of machinery in specific shifts.

A common example of use is the time switch to turn on street lights at dusk and turn them off at dawn, optimizing energy consumption.

Productos recomendados

Ver Productos

Ver Productos

Ver Productos

Ver Productos

Main types of timers

Analog programmable switches are simple devices with a 24-hour dial that allow you to set on/off cycles, ideal for basic applications such as controlling lights or appliances.

Safety Switches

Safety switches are manually operated switches or switches actuated by safety mechanisms, generally with a robust construction. They are designed to ensure the protection of people and equipment in hazardous situations by shutting down machinery or cutting off the power supply when needed. In addition, they are usually locked until manually reset.

Main applications

- Protection of operators and equipment in industry: Emergency stop switches are placed on machinery, production lines or elevators. When activated, they safely stop the movement of the machine.

- Safety interlocks: Installed on cage doors or dangerous machine enclosures, these switches cut off the power supply if the doors are opened, preventing accidents.

Main types of safety switches

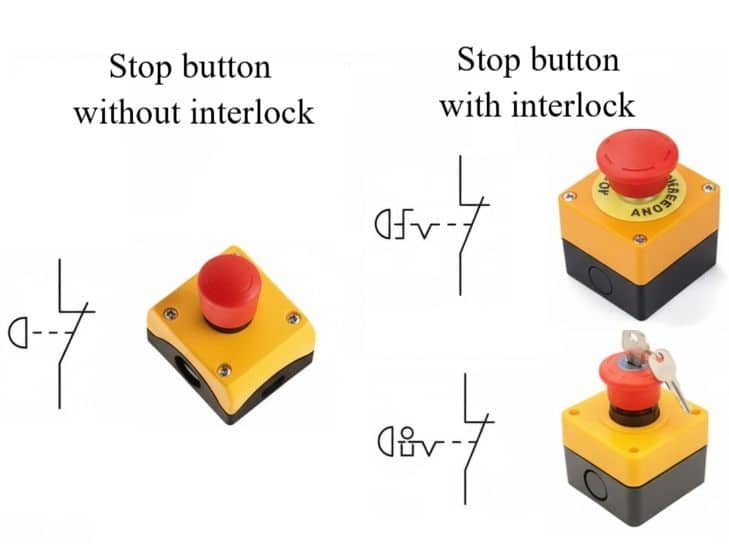

The most common types include the emergency stop button, which immediately stops operation with a single touch and locks until manually reset, and safety interlock switches, which stop the machine when doors or guards are opened, ensuring that access to hazardous areas is safe.

There are also emergency stop interlock switches, which combine both functions for added safety, and door-operated safety switches, which deactivate the system when access doors to hazardous areas are opened. All of these devices are essential to ensure functional safety in industrial environments and to comply with safety regulations.

symbol of a stop button

Example of a stop button without and with interlock.

Position Switches

Position switches, also known as limit switches, are electromechanical devices designed to detect the presence or position of a moving part of a machine. They are devices actuated by the movement of an object, usually by means of an actuator (lever, plunger, roller), which, when moved, closes or opens the internal contacts of the switch.

Main applications of position switches

Position switches are mainly used in industrial automation to detect the end of travel or limit positions of various mechanisms. They are common in machine tools, elevators, conveyors, robotics, among others.

In a motorized gate, a limit switch indicates whether the gate is fully open or closed. In a press, it is used to detect the lowest position of the plunger. They also have applications in domestic systems, such as door/window open detectors in alarm systems. Their reliability and simplicity make them essential for process control and automation.

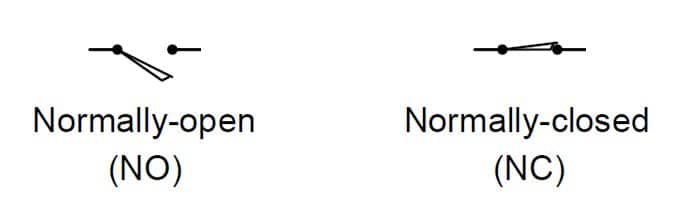

Contact types in position switches

- Normal-open (NO): The switch remains open in its normal state and closes when activated, allowing current to flow only when the switch is actuated.

- Normal-closed (NC): The switch remains closed in its normal state and opens when activated, interrupting current flow when the switch is actuated.

- SPDT (Single Pole Double Throw): A toggle switch that has a single pole and two outputs, allowing the circuit to switch between two different states.

symbol of the nc and no switches

Isolation switches

Better known as disconnectors, isolation switches are devices designed to electrically isolate a circuit when it is open, ensuring a safe disconnection for maintenance work or in emergency situations.

The contacts of a disconnector have a high separation distance or interlocking mechanisms to ensure that, once open, the circuit is completely isolated and safe to work on.

Unlike other circuit breakers, disconnect switches are not intended for switching live loads (many do not have load breaking capacity).

Main applications of a disconnector

Disconnect switches are primarily used for the safe disconnection of circuits prior to maintenance work. Some of their most common applications include:

- Disconnection of main feeds in switchboards (e.g., general head-end disconnector).

- Isolation of medium voltage switchgear, transformers and battery banks.

- In motor control centers, a disconnector with front handle disconnects the power supply of the entire panel for maintenance, and can be locked with a padlock for added security.

- In homes, the main switch of a switchboard functions as a disconnecting switch (although it usually also acts as a circuit breaker).

Types of Disconnectors

- Knife switches: These are the oldest and use a metal blade to open or close the circuit. Although they are simple, they are mainly used in old or low voltage installations.

- Knife-blade isolators: They are similar to the knife switches, but with greater capacity to cut off large loads. They are used in low voltage alternating current systems.

- Rotary isolators: They have a rotating mechanism to disconnect the circuit. They are common in industrial applications due to their reliability and ease of use.

- Fuse switch: They combine the function of a disconnector and a fuse, providing additional protection against overcurrents. They are ideal in systems where a safe disconnection and extra protection is needed.

- Load isolator: They are designed to disconnect the circuit under load conditions. They are more robust and are used in applications where the disconnection of active equipment is essential.

Pressure Switches

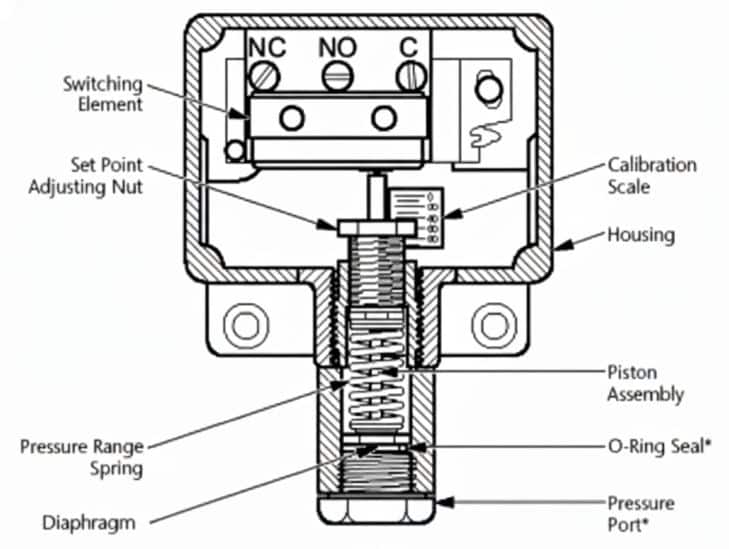

Pressure switches or pressure switches are sensors with integrated electrical contact that are activated when the pressure of a fluid reaches a certain threshold value. These switches are controlled by a pressure-sensitive element, such as a diaphragm, plunger or Bourdon tube, which deforms when pressure is applied and activates an internal microswitch.

These devices are set to trip at a specific pressure, called the actuation point, and usually have hysteresis (differential between opening and closing pressure). In short, it opens or closes its contacts depending on the pressure in the system.

Main applications of a pressure switch

- Pump and compressor control: In systems such as hydrophores or air compressors, a pressure switch turns the pump on when the pressure drops below a preset value and turns it off when it reaches a set high pressure.

- Protection of hydraulic and pneumatic systems: They help prevent overpressure by triggering alarms or shutting down the system if a dangerous pressure threshold is exceeded.

- Boilers and air conditioning: They are used to verify the presence of pressure (e.g. air, gas or refrigerant flow), as a safety condition.

- Control in industrial lines: Activate fans, valves or control sequences when a specific pressure is reached in industrial processes.

Types of pressure switches

- Single acting pressure switches (SPDT): These are the most common, with a single pole and two switching contacts (open/closed). They are used to control a single circuit and are ideal for simple applications such as pump and compressor control.

- Double acting pressure switches (DPDT): They have two poles and two switching positions, allowing to control two independent circuits. They are used in more complex applications where it is required to control several devices at the same time.

diagram of a pressure switch

A type of electrical switch for every need

As you have seen, there are several types of circuit breakers, each designed to meet specific needs in both residential and industrial electrical installations.

Remember that in our electrical material section you will find, in addition to switches, everything you need for your electrical installations.